Washing Machine Matching Solution (Coil Coatings for Home Appliance Panels) Water Heater Solution(Coil Coatings for Home Appliance Panels) Color TVs Solution(Coil Coatings for Home Appliance Panels ) Refrigerator Solution (Coil Coatings for Home Appliance Panels) Building Wall Coating Coil coatings for building roof panels

2-Coating system for petrochemical equipment and facilities2 1-Coating system for petrochemical equipment and facilities1 Anti-corrosion coating system for marine engineering equipment

Car Refinish Paint Products Functional E-coatings for frames, etc. High - performance Cathodic E-coatings for Vehicle Bodies E- Coatings for Automotive Components Cathodic Electrophoresis for Home Appliances

1. Product composition: The coating is composed of A, B and C three components:

LR-333A: The main components of the silver paste are ultra small flake-shaped Zn, ultra small flake-shaped Al and alcohol compounds.

LR-333B:It is the solvent component of the coating, mainly an orange-red aqueous solution containing Cr6+.

LR-333C:It is the adhesive component of the coating, mainly cellulose white or slightly yellow powder.

2. Application: Zinc-based chromate coating is a new technology of surface treatment to achieve surface corrosion protection which can replace galvanizing, hot spraying zinc, etc., zinc-based chromate coating is also called Dacromet, compared with the traditional electroplating process, is a kind of "green electroplating". No pollutant emissions, no hydrogen embrittlement occurs.The film is silver-white, with good surface finish, high corrosion resistance and good recoating performance..

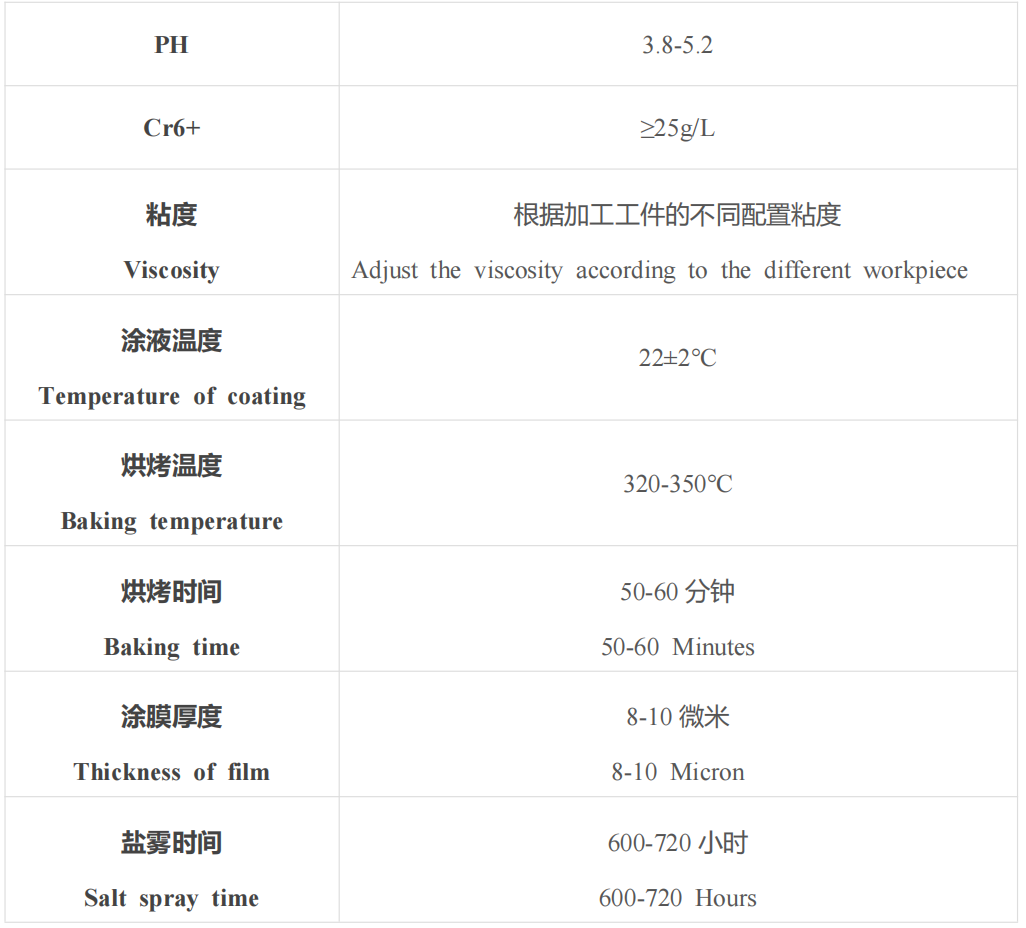

3. Product technical parameters

The above parameters are the operating fluid indicators

4、 Preparation of coating

1. Preparation Technique

1.1 Preparation of Coating

LR-333 Ratio of zinc-based chromate (DACROMET)

Agent A: 16 KG

Agent B: 24 KG

Agent C: Can be determined according to different construction requirements (The amount of Agent C can be appropriately reduced during spraying to achieve spraying viscosity)

1.2 Before configuration, the temperature of the weighed Agent A and Agent B was maintained at 22±2 ° C by indirect water bath, and then use a frequency conversion mixer to fully stir the Agent A to make the metal slurry completely dispersed and uniform.

1.3 Add Agent B slowly into the stirring Agent A barrel, the temperature in the barrel will slowly rise at the same time, keep the temperature of the coating liquid at about 22℃ while stirring.

1.4 After Agent B is added, keep stirring continuously for 1 hour, and then add Agent C. If Agent C has clumps, it must be powdered and then added slowly. Continue stirring at a slow speed for 8 hours to facilitate the maturation and defoaming of the Dacroment coating.

1.5 After mixing, pouring into the immersion tank and filtering with 80 mesh stainless steel filter.

1.6 The dip coating tank in the construction site must have a temperature control device to maintain the temperature of the coating solution at 22±2℃ (the coating is easy to age if the temperature is too high and that will affect the viscosity ), and the coating has to keep circulating to maintain uniform dispersion and prevent precipitation.

5.Coating process

1 Degreasing

Greasy workpiece must be surface degreasing, there are two methods: degreasing with high temperature of neutral water-based degreasing agent.

2 Remove rust and burrs

All rusted or burred workpieces are strictly prohibited to be coated directly, it must be derusted and burred before construction. This process is best carried out by shot blasting and sand blasting. Acid washing will affect the corrosion resistance of Dacroment coating.

3 Coating

The clean workpiece after degreasing and derusting must be coated by brush, dip, or spray as soon as possible.

4 Pre-baking

The pre-processing workpiece coated with Dacroment coating must be prebaked for 8-15 minutes at a temperature of 150-180 ℃ (the temperature and time need to adjust according to the heat absorption of the workpiece), so that the water of the coating will evaporate and the flow will be evenly uniform.

5 Sintering

The pre-baked workpiece must be sintered at a high temperature of 320-350 ° C for 50-60 minutes (the temperature and time need to adjust according to the heat absorption of the workpiece), and the temperature can also be appropriately increased to shorten the sintering time.

6. Notes

1.Should not mixed other chemicals such as various acids, alkali salts and so on into the coating, because these chemicals can activate the flake of zinc and aluminum in the coating, so that aging the coating solution.

2.Pay attention to avoid sunlight and ultraviolet irradiation for a long time in the process of construction, the long time irradiation will accelerate the aging of the coating, and cause polymerization and gelling.

3 It is very important to manage the temperature of the coating. The change of the temperature of the coating will affect the viscosity, and the change of the viscosity will affect the coating amount of the workpiece. So the relationship between the temperature, viscosity, and the centrifuge drying process should be adjusted in the coating process.

4. Viscosity requirements are not the same because of different coating methods. At 22 ℃, spraying viscosity is 30-40 seconds (Zahn 2# Cup), dipping viscosity is 50-60 seconds (Zahn 2# cup) .

7、 Storage and packaging

1. LR-333A liquid is packed in 16kg iron drum; LR-333B liquid is packed in 24kg plastic drum; LR-333C is packaged in small iron drums. (Vats packing in special cases)

2. Under the condition of 20℃, the storage period of Agent A and Agent B components is six months. The prepared coating can continue to be recycled under the condition of continuously adding new coating, and it is store below 15℃ when the coating is not in use.

Copyright © 2025 Jiangyin LongRun Coating Co., Ltd Record number:Su ICP No.2025160119